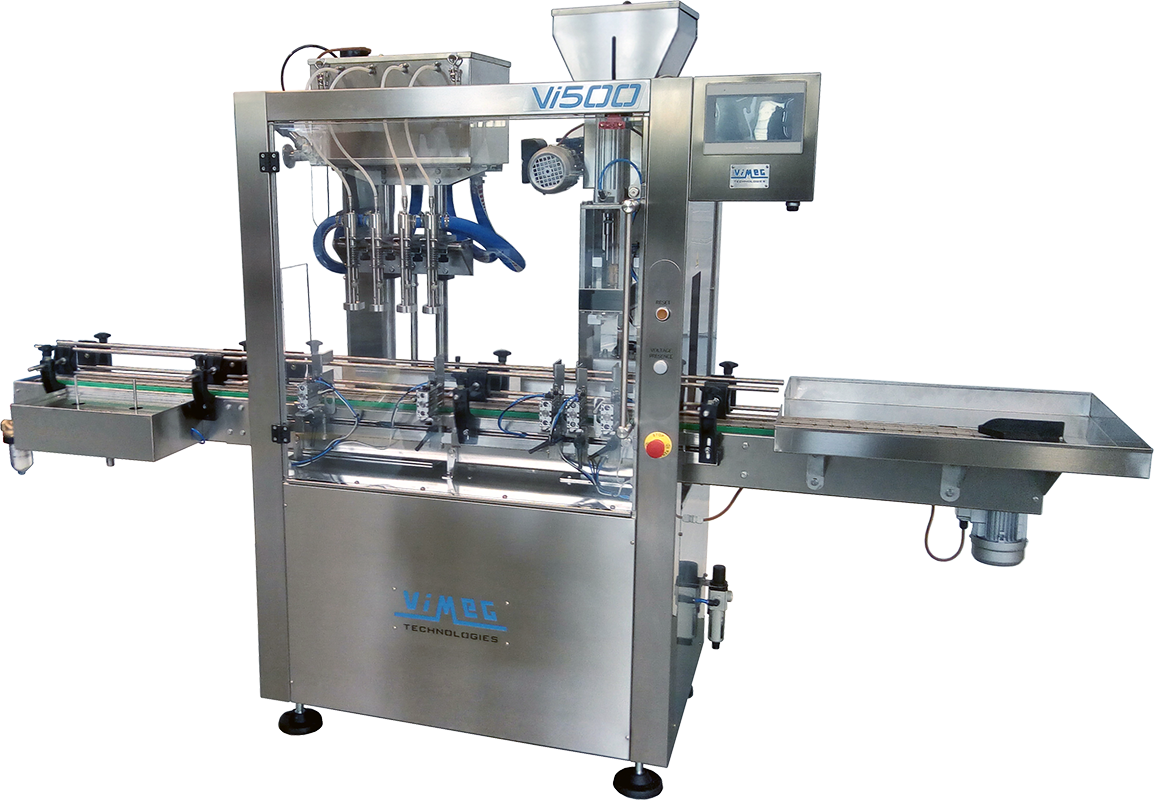

The Vi500 4-1V Monoblock by ViMEG is a fully automatic bottle filling and screw capping machine. The Vi500 4-1V has a production rate of 200 - 600 bottles per hour. The self-contained unit is complete with load & unload trays, chain conveyor, filling hopper, cap hopper with loading arm for the caps, single descending screw cap head, motor, and on-board touch screen control unit to operate the machine.

The conveyor smoothly carries the bottles to the filling station, where the nozzles are automatically lowered into the bottles, creating an air-tight seal to fill the bottles whilst purging the oxygen. Once filled the bottles are transferred to the capping station via the conveyor where optical sensors are used to ensure each bottle opening is correctly aligned for precise application of the ROPP cap. The capping head is designed and tuned specifically for the ROPP cap and bottle it is to be used with. The descending cap track contains a photocell sensor to ensure the presence of a cap in the feed channel. The PLC control unit with on-board variable frequency drive allows you to adjust the speed of operation as well as set & save preset configurations, keep track of the bottle count, and perform diagnostics.

To watch the Vi500 4-1V Filler and Screw Capper operate CLICK HERE

To learn more about ViMEG CLICK HERE

The conveyor smoothly carries the bottles to the filling station, where the nozzles are automatically lowered into the bottles, creating an air-tight seal to fill the bottles whilst purging the oxygen. Once filled the bottles are transferred to the capping station via the conveyor where optical sensors are used to ensure each bottle opening is correctly aligned for precise application of the ROPP cap. The capping head is designed and tuned specifically for the ROPP cap and bottle it is to be used with. The descending cap track contains a photocell sensor to ensure the presence of a cap in the feed channel. The PLC control unit with on-board variable frequency drive allows you to adjust the speed of operation as well as set & save preset configurations, keep track of the bottle count, and perform diagnostics.

To watch the Vi500 4-1V Filler and Screw Capper operate CLICK HERE

To learn more about ViMEG CLICK HERE

DETAILS

- Production: 200 - 600 bottles per hour

- Touch screen control unit with variable frequency drive to adjust speed of conveyor and cap application

- Single ROPP capping head specifically designed and tuned for each bottle and cap configuration

- Descending nozzles and capping head accommodate bottles up from 3.2 - 18 inches in height

- Conveyor movement capable of handling conventional and unconventional bottle shape and size

- Requires air supply of 120 PSI, 10.5 CFM

- Rquires external pump to transfer fluid to filling tank

- AISI 304 stainless steel construction

- Power: 2.0 HP, 220v 1 PH, 6.0A

- Dimensions: 120" L x 52" W x 76" H, 1500 lbs

- Made in Italy

Options available upon request:

Your Trusted Source for Winery, Cider, Distilling Equipment & Supplies

- Semi-automatic Rinsing & Drying station with on-board air and water filters

- Upgraded ultrasonic sensors for transparent bottles

- Nitrogen injection station before filling

- Nitrogen injection on capping head

- Vacuum on capping head (with on-board compressor)

Your Trusted Source for Winery, Cider, Distilling Equipment & Supplies