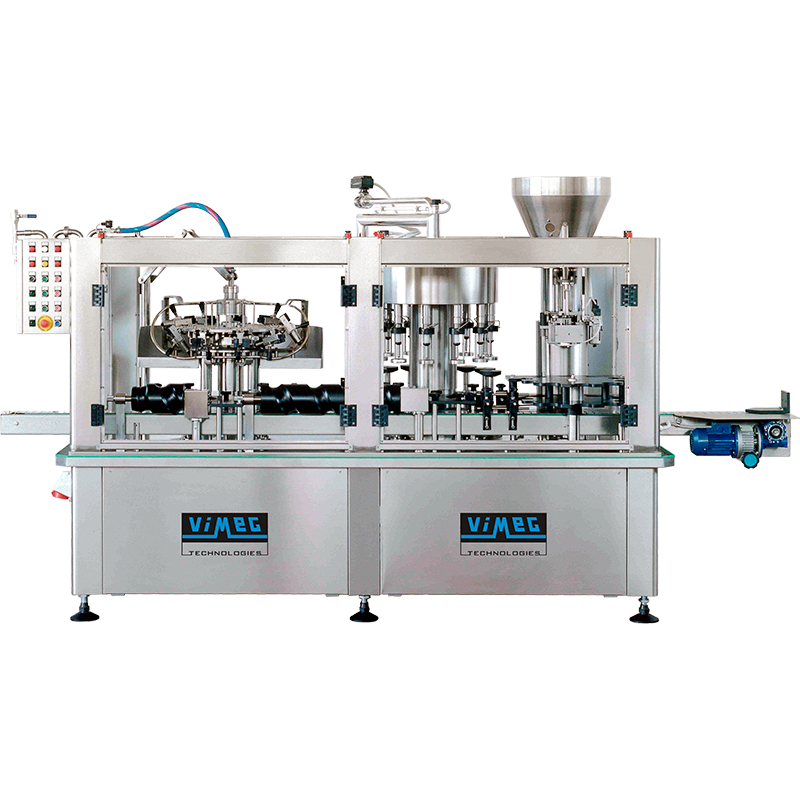

The BLUE LINE 3-S Triblock by ViMEG is a fully automatic bottle rinsing, filling and corking machine. A small amount of liquid (filtered water or no-rinse sanitizer) is sprayed into the bottles before they are swung vertical and rotated to ensure that they are uniformly cleaned and dry before being filled. A light vacuum is introduced to the bottle while filling- removing the displaced air to minimize the liquid's exposure to oxygen and reduce the risk of oxidation.

The BLUE LINE 3-S can be produced with 9, 12, or 16 rinsing nozzles; and 12 or 16 filling spouts, providing a production rate of up to 3000 bottles per hour. The self-contained unit is complete with its own conveyer belt for loading and unloading bottles, filling hopper, cork hopper with loading arm for the corks, single corking head, motor, and on-board control unit for operating the machine and adjusting the production speed. The in-feed screw smoothly transitions the bottles from the conveyor to the revolving starwheel where they are precisely positioned atop automatic lift plates that raise the bottles to the filling nozzles. The subsequent revolving starwheel secures the base of the bottle at the point of corking, while individual microsensors ensure that the bottle opening is correctly aligned for precise application of the cork. The on-board variable frequency digital control allows you to adjust the speed of both the conveyor, filling nozzles, and corking piston, as well as switch between automatic and manual filling and corking on the fly. The descending cork track contains a photocell sensor to ensure the presence of a cork in the feed channel.

The BLUE LINE 3-S is modular and can be operated as a stand-alone unit or in a fully-integrated series with other ViMEG machines.

To see a video of the BLUE LINE 3-S Rinser, Filler & Corker operate CLICK HERE

The BLUE LINE 3-S can be produced with 9, 12, or 16 rinsing nozzles; and 12 or 16 filling spouts, providing a production rate of up to 3000 bottles per hour. The self-contained unit is complete with its own conveyer belt for loading and unloading bottles, filling hopper, cork hopper with loading arm for the corks, single corking head, motor, and on-board control unit for operating the machine and adjusting the production speed. The in-feed screw smoothly transitions the bottles from the conveyor to the revolving starwheel where they are precisely positioned atop automatic lift plates that raise the bottles to the filling nozzles. The subsequent revolving starwheel secures the base of the bottle at the point of corking, while individual microsensors ensure that the bottle opening is correctly aligned for precise application of the cork. The on-board variable frequency digital control allows you to adjust the speed of both the conveyor, filling nozzles, and corking piston, as well as switch between automatic and manual filling and corking on the fly. The descending cork track contains a photocell sensor to ensure the presence of a cork in the feed channel.

The BLUE LINE 3-S is modular and can be operated as a stand-alone unit or in a fully-integrated series with other ViMEG machines.

To see a video of the BLUE LINE 3-S Rinser, Filler & Corker operate CLICK HERE

DETAILS

- Production: 800 - 3000 bottles per hour

- Digital control unit with variable frequency drive to adjust speed of conveyor and cap application

- Single Capping head for Cork (natural, agglomerate, & synthetic, sizes #7 - #10)

- Air injection on corking piston to remove cork dust

- Multiple rinse nozzle and fill spout configurations:

- 9 Nozzle, 12 Spout: 800 - 2000 bph

- 12 Nozzle, 12 Spout: 800 - 2400 bph

- 12 Nozzle, 16 Spout: 800 - 2600 bph

- 16 Nozzle, 16 Spout: 800 - 3000 bph

- Operable as single unit or in series with other ViMEG machines

- Adjustable lift plate and descending head accommodate bottles up to 15 in (375 mm) in height

- Universal starwheel can be replaced to accommodate unconventional bottle shape and size

- AISI 304 stainless steel construction

- Power: 1.8 kW, 240v, 3 PH, 7.5A

- 4500 lbs

- Made in Italy

Optional Features:

CALL FOR PRICING & AVAILABILITY

WINEMAKERS DEPOT

Your Trusted Source for Winery, Cider, Distilling Equipment & Supplies

- Touch-screen Control Unit

- 100 editable presets for material, bottle, & cap variants; fill level, operating speed, etc.

- Bottle Counter

- Error Diagnostics with photocells at:

- Machine Exit - stop machine if collection tray is full

- Loading Hopper - stop machine if hopper is empty

- Capping Outlet - stop machine if cap is misloaded or improperly applied

- Nitrogen injection prior to filling nozzles

- Nitrogen injection on corking head

- Vacuum on corking head (with on-board compressor)

CALL FOR PRICING & AVAILABILITY

WINEMAKERS DEPOT

Your Trusted Source for Winery, Cider, Distilling Equipment & Supplies