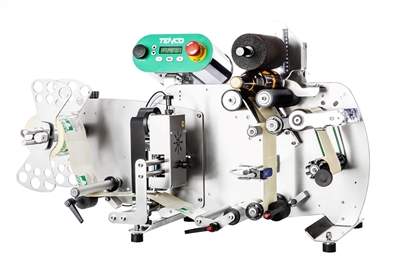

Tenco M2R Semiautomatic Labeling Machine

Tenco M2R Semiautomatic single reel bench top labeling machine for round bottles, conical and square bottles with the installation of the related accessory. Application of front and back label on round bottles from the same reel on a single cycle. Application of front and back label on square bottles on two cycles by turning the bottle of 180°. Also recommended for containers having a low mechanical resistance to pressure (i.e. plastic as PET, PE, PVC and so on). Datalogic fork photocell with a 50 mm slot and teach in button. Leuze ultrasonic fork photocell available for transparent labels. 170 mm paper passage (standard), tall rollers up 220 mm as an option. The great advantage of this machine is the capability of labeling round and square bottles (with the related accessory) without the need of mounting / dismounting mechanical parts. It is sufficient to follow the correct paper path according to the required application and make some simple adjustment in compliance to the bottle format and the label(s) size. Productivity: about 600 bph (round bottles – front and back). About 350 bph (square bottles front and back label).

Details:

WINEMAKERS DEPOT - Your Trusted Source for Bottling and Labeling Equipment

Tenco M2R Semiautomatic single reel bench top labeling machine for round bottles, conical and square bottles with the installation of the related accessory. Application of front and back label on round bottles from the same reel on a single cycle. Application of front and back label on square bottles on two cycles by turning the bottle of 180°. Also recommended for containers having a low mechanical resistance to pressure (i.e. plastic as PET, PE, PVC and so on). Datalogic fork photocell with a 50 mm slot and teach in button. Leuze ultrasonic fork photocell available for transparent labels. 170 mm paper passage (standard), tall rollers up 220 mm as an option. The great advantage of this machine is the capability of labeling round and square bottles (with the related accessory) without the need of mounting / dismounting mechanical parts. It is sufficient to follow the correct paper path according to the required application and make some simple adjustment in compliance to the bottle format and the label(s) size. Productivity: about 600 bph (round bottles – front and back). About 350 bph (square bottles front and back label).

Details:

- Front and Back Label Capability

- For round containers with a diameter between 35 and 120 mm (max conicity 1°)

- Square Bottle Attachment Option Will Display In Drop Down Menu

- For Glass, Plastic or Metal Bottles

- Option Available for Hot Foil Printer

- Option Available for Ink Printer for Date or Lot

- Photocell, also known as “detector” for the application of transparent labels

- Production: 600 BPH Round Bottles Single or Double Labeling

- Production: 600 BPH Square Bottles Front only (350 BPH Front and Back)

- Labels application accuracy ± 3 mm

- Analogical control board

- 1 Labeling head (front and back from the same reel)

- Paper passage: maximum 170 mm

- Reel maximum external diameter: 280 mm

- Supply: 110 V 60 Hz single-phase

- Power consumption: 0,3 KW

- Weight: 37 Kg

WINEMAKERS DEPOT - Your Trusted Source for Bottling and Labeling Equipment